6 Types of Structural Steel Sections, and How They’re Used

Steel is one of the best materials for providing strength and structural soundness for any product — which is important when it comes to construction projects. With steel, you can create structural steel pieces with unparalleled potency, durability, and flexibility, which is why it has undoubtedly become the preferred choice for construction.

Engineers have applied structural steel to millions of projects, creating massive skyscrapers and expansive bridges that have remained for hundreds of years. To help you understand the full potential of this material, here is an overview of the basic types of structural steel sections, and how they’re used.

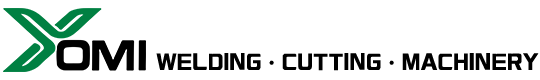

Multi-channel Horizontal H Beam Production Line H-beam can be made in single process.

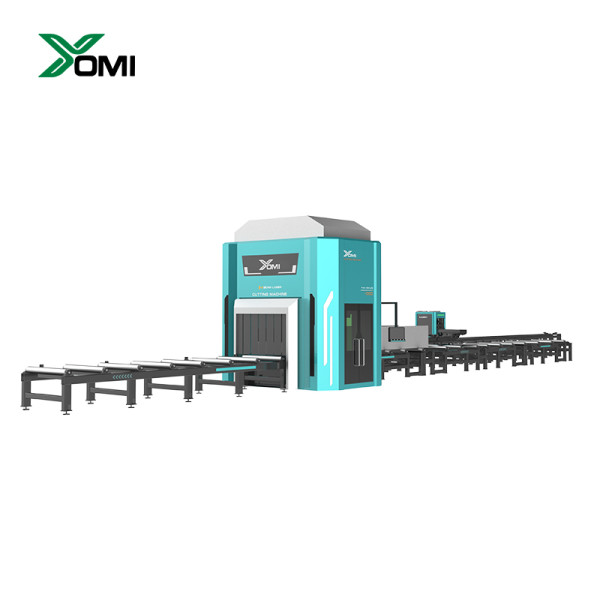

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

Angles

These are steel beams with an L shape and come in many lengths and sizes. In this, two steel legs come together at a 90-degree angle, and each leg may be unequal or equal in length. For example, an unequal angle might have one leg of 6x2x0.5, and another that is 3x2x0.5.

This kind of structural section is typically used in floor systems due to their reduced structural depth but enhanced strength-to-weight ratios. You mainly see them in infrastructure, residential buildings, mining, and transport applications.

Beams

These are your standard steel beams, which are used together with steel girders. They come in three shapes: standard or “S” beams, wide flange or “W” beams, pile or “H” beams, and “T” beams.

“S” beams have tapered flanges, while “W” beams have parallel flanges. “H” beams, also called universal beams, are shaped like their namesake. They may also be called “I” beams because they look like the letter when standing upright. These structural steel pieces are widely used in construction and civil engineering, among other industries. They are usually fabricated in lengths up to 60 ft.

“T” beams are slightly different. They lack a bottom flange — the top of their cross-section is a flange, which is connected to a vertical web below. Because of their shape, they’re usually applied as a load-bearing section, but they have a disadvantage in some applications.

Bearing Piles

When construction workers and engineers are unable to find or create a strong enough foundation on the worksite, they make use of structural steel products called bearing piles. Bearing piles are used to create a deeper foundation system, which is more stable and structurally sound.

Bearing piles are H-shaped steel pieces, whose design allows them to effectively transfer loads through the pile to the tip. It’s extremely durable and efficient — it can bear more than a thousand tonnes of weight. Bearing piles work best in densely packed soil, as they offer more resistance at the tip. Common types of bearing piles include h-piles, screw piles, pipe-piles, and disc piles.

Channels

Channels are somewhat similar to steel beams, as they both have webs flanked by flanges. The difference is that their webs are oriented off to the side, and the flanges are oriented perpendicularly to the web. This design makes them especially suited for bridges and similar structures, but they have also found their place in other marine and building applications.

Channels can be manufactured in lengths of up to 60 ft, but the standard sizing usually falls in the 20 to 40 ft range. Channels can’t be applied in the same way that beams are, as they aren’t flat on all sides. Instead, their one flat surface allows them to be bolted up against other flat faces.

Hollow Structural Sections (HSSs)

Hollow structural sections (HSSs) are steel profiles with a hollow section and can be fabricated into square, circular, rectangular, and elliptical shapes. HSSs profiles are slightly rounded, with radiuses that are about twice the value of their wall thickness. HSSs are commonly used by engineers in welded steel frames to create structures that have the capacity for carrying loads in different directions.

The different HSS forms have various advantages and recommended applications, which you can read here. Typically, they are great in multi-axis loading processes, joining and metal fabrication, and creating columns and posts.

Plates

This structural steel section is arguably the most versatile piece in this list. They can be cut and further processed into different sizes and shapes, depending on the application. This is necessary as they don’t stand on their own — they require attachment to another structural steel section to be usable. In some cases, plates are attached to other steel pieces to reinforce the structure.

The most common type of structural steel plates is called base plates. These are used when the foundation is shallow, uneven, or difficult to work with. In these bases, base plates are applied to a column, which helps them to dis