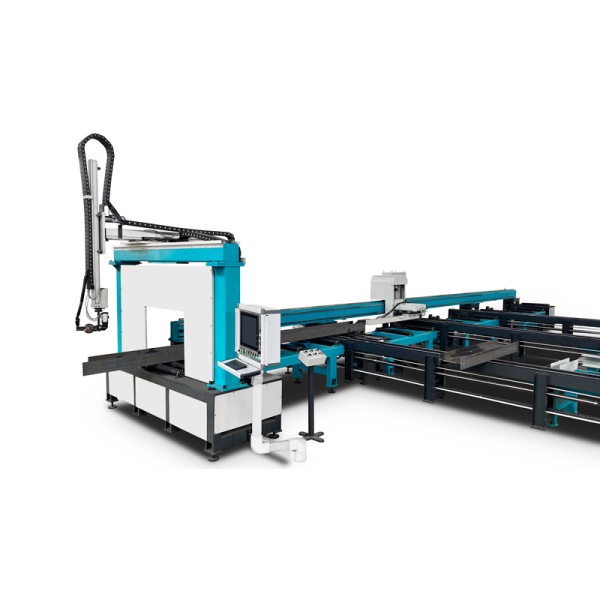

CNC Beam Plasma Cutting Machine

| Share | |

|---|---|

| Categories | H Beam Cutting Machine |

| Brand | YOMI CNC Cutting&Welding Machinery |

| Model | YM-XH-600/1000/1250/1500 |

| H beam size | 100mm-1000mm 100-600mm |

| Channel steel size | 100mm-1000mm 100-600mm |

| Cutting method | Plasma/Flame |

| Plasma power source | Herpertherm XPR300 or optional |

| Plasma cutting thickness | It is depended by plasma power source |

| Oxyfuel cutting thickness | Vertical cutting thickness 6-32mm |

| Effective cutting length | 12000mm |

| Cutting precision in length | ±1.5mm |

| Cutting speed | 10~2000mm/min |

| Moving speed | 10~6000 mm/min |

| Update Time | Feb 15,2026 |

YOMI Patented invention, this machine is widely used in steel structure and large frame structure as a special processing equipment for H beam cutting.

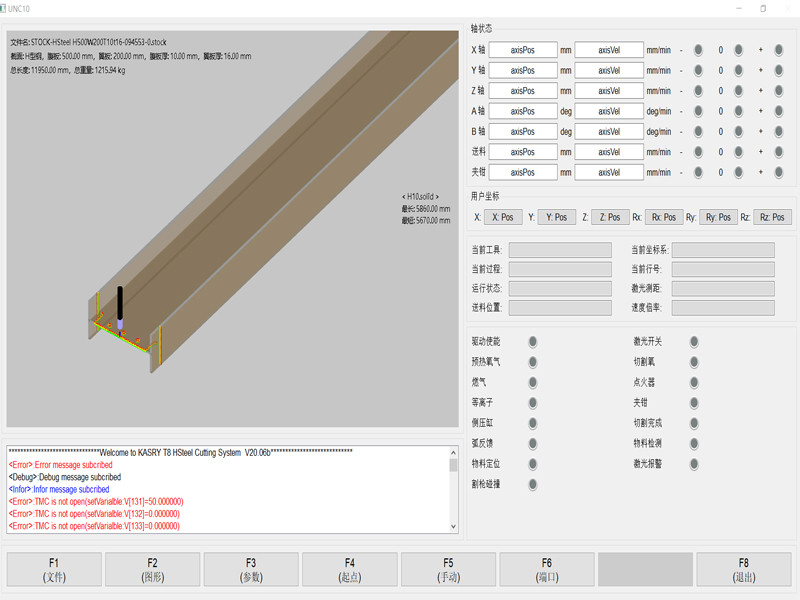

Advanced intelligent cutting control system,it can generate G code directly,3D simulation operation,node expansion, ultra long profile partition; profile cutting optimization.It can be applicable to 3D cutting for all kinds of profile (H-beam, I-beam, angle beam, channel beam and others).

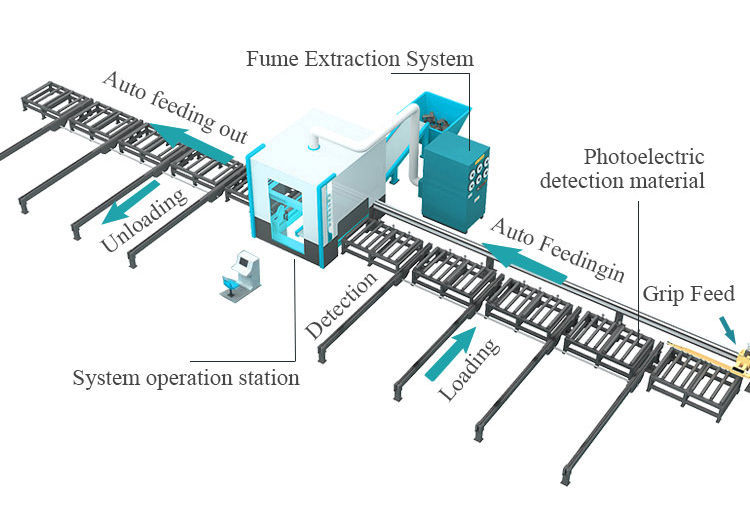

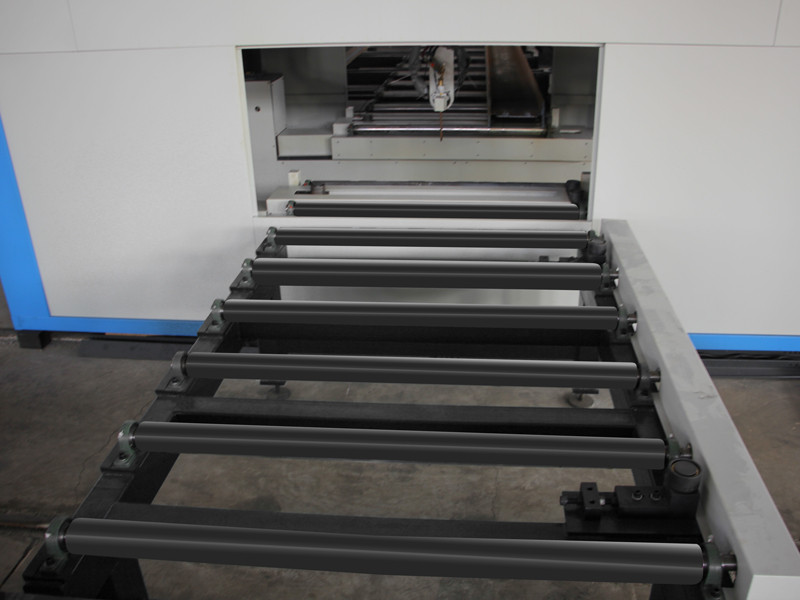

Loading Unit

Feeding In Rollers

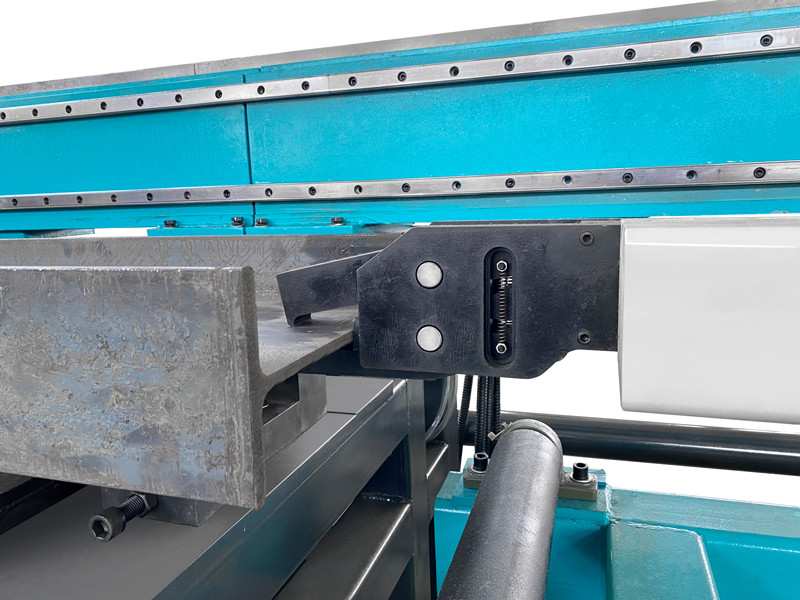

Hydraulic Clamp

Cutting Unit

Feeding Out Rollers

Output Side Positioning Reference

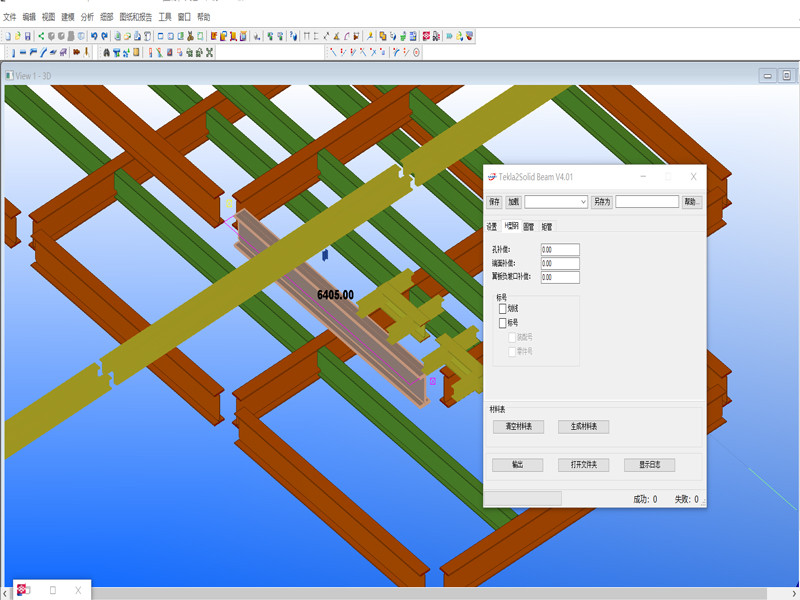

lSupport TEKLA steel structure deepening software 3D modeling data file cutting.

lSupport AUTOCAD 3D modeling file programming compilation.

lTrack path automatic optimization processing.

lTEKLA software exports NC files and batch generate G code.

l3D component preview.

lComponent nesting optimization.

lSupport all kinds of overlapping forms and bevel cutting.

lLaser sensor detection to solve position deviation.

lTorch anti-collision function.

lSolve the problem of thickness plate perforation, with dynamic pierce function,protect the cutting nozzle and improve the service life of consumable parts.

lWith high- definition hole cutting function.

lIntelligent marking.

lSupport Hypertherm XPR300 interface 422 communication protocol, automatically switch cutting process parameters.

Item |

Parameters |

||

H Beam Size | 100mm-600mm | ||

Channerl steel size | 100mm-600mm | ||

Cutting method | Plasma cutting | ||

Plasma power source | Huayuan 300A or Optional | ||

Effective cutting length | 12m | ||

Length cutting accuracy | ±1.5mm | ||

Cutting shape | According to drawings confirmed by both parties(It will be provided when technical agreement signed) | ||

|

Cutting speed

|

10~3000mm/min

|

||

|

Moving speed

|

10~9000 mm/min

|

||

Maximum profile weight |

1000kg

|

||

Profile cutting form | Fixed length straight cut, fixed length oblique cut and end socket function | ||

Cutting accuracy execution standard | ISO9013-2002\ISO8206-1991\ JB/T10045.4-1999JB |

|

1

|

2

|

3

|

4

|

5 |

|

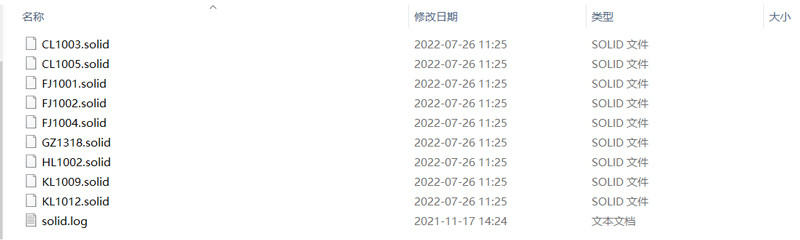

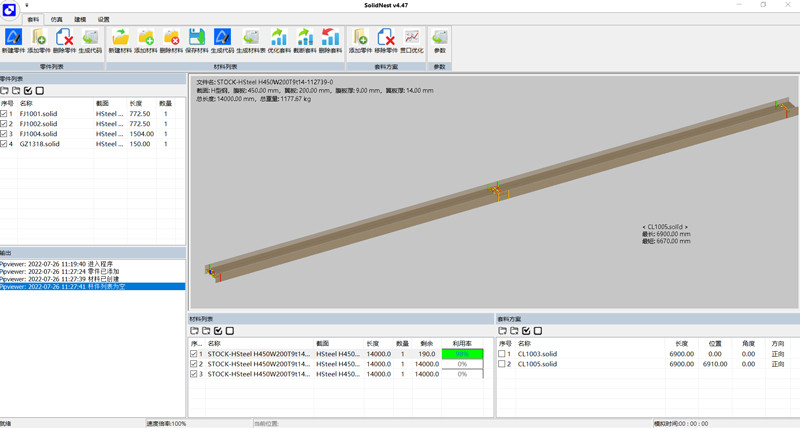

TEKLA DSTV NC1 file generate.Through software BCS&BMS V1.09P Automatic& batch generate PIP cutting code file.

|

Pass the single piece cutting code file through the PIPNEST nesting software, automatically optimize the combination to generate the nesting program and material table statistics.

|

Visually view the cutting trajectory, check the cutting length and component weight with the 3D graphics preview software PIPVIEWER1.03

|

Gallery programming directly enters profile specifications via dialog window, calls process category conversion cutting code

|

After the code is completed, transfer the cut file to the device, job preparation |

|

1

|

2

|

3

|

4

|

5 |

|

Machine start inspection, including plasma power and gas pressure

|

Profile preparation, feeding to the input roller side to the positioning datum

|

Cutting program called, Clamp automatic height positioning, Automatic transfer to cutting station

|

Start cutting(laser detection, collision pause), slag discharge,finished cuttings output

|

Finished cuttings to output storage area |

- Loading...

- Name

- Phone

- *Title

- *Content

- Name:

- YOMI WhatsAPP

- Tel:

+0086-13153107480

- Email:

- sales@yomi-china.com

- WhatsApp:

- 8613153107480

- Address:

- Factory Adress: 9 Changjie Road, Ningjin,Dezhou, P.R.China